Battery Element Testers

Model : Battery Element Testers

Q'ty :

- Battery Element Testers

- Battery Element Testers 1

- Battery Element Testers2

- Battery Element Testers 3

All STS Battery Element Testers provide a unique method for the detection of assembly level insulation defects in lead-acid batteries, including missing and damaged separators. Detection of such faults prior to filling and charging the battery minimizes costly reclamation. Traditional AC dielectric tests can detect such faults, but may produce damaging heat in moist cell applications. To overcome this limitation, STS has developed testers that employ a high-voltage, short duration pulse to maximize stress to the dielectric material while minimizing average energy. The goal is to provide sufficient stress to cause current flow in the presence of a failure. This technique allows reliable fault detection while eliminating damage due to overheating that may occur with an AC test.

All testers feature an adjustable test voltage with a peak output of 3,000 volts, accommodating a wide range of separator spacing and types. Durable solid state switching of the high voltage assures reliability for high volume applications. Easy-to-read displays provide readouts for applied voltage and quality readback. Following a simple setup procedure, operation is go/no-go, and requires no operator interpretation of results. The test voltage is applied using included safety probes. When a failure occurs, the high voltage is shut off and both audible and visual alarms warn the operator of the failure.

| AC OUTPUT | |

|

VOLTAGE RANGE RESOLUTION |

300 to 3000 Volts Peak, adjustable 10V |

|

ACCURACY SHAPE |

± 2.0% Pulse |

| DURATION | 15 us typ. |

| TEST INTERVAL | Programmable from 30 ms - 5000 ms |

| MEASURMENTS | |

| VOLTAGE |

Range: 0 to 3000 Volts Peak Resolution: 1 Volt Accuracy: ±0.2% F.S. . |

| QUALITY METER |

Range: 10 to 3750 Resolution: 1 Accuracy: ± 2.0% |

| AC INPUT | |

| INPUT VOLTAGE |

100V to 240V ± 10% Universal Input. Frequency: 47 - 63 Hz AC Current: 500 mA max. |

| POWER FACTOR | 0.98 Typical |

| FUSE | 0.5A Slow Blow 250VAC. (5 x 20 mm) |

| LINE CORD | Detachable, IEC 60320, C13 Type Line Cord Included |

| REGULATORY | |

| APPROVALS |

CE Mark LVD 2006/95/EC Safety: IEC 61010-1:2010, Ed 3.0 EMC: IEC 61326-1:2012, Ed 2.0 |

| FRONT PANEL CONTROLS AND INDICATORS | |

| POWER | Illuminated On/Off Rocker Power Switch Lit when unit is powered on |

| CHECK | Red Illuminated Check Button Verifies Tester Operation |

| RESET | Green Illuminated Reset Button |

| ADJUST/ENTER DIAL | Allows for Easy Scrolling through on-screen menu fields and adjustment of parameters and test levels |

| LCD DISPLAY | 480x272 pixel high-resolution graphical color LCD with white LED backlit. 4.2" diagonal size |

| KEYS |

MENU: Displays Main Menu LOCAL: Returns Front Panel Control ESC: Backs up to Undo last entry LOCK: Lock out Front Panel Control VOLT1 to VOLT3: Sets preset Test Level TRIP1 to TRIP3: Sets preset Trip Level |

| TEST PROBES | High Voltage detachable probes w/ leads |

| PHYSICAL | |

| DIMENSIONS (WxHxD) |

1656: 425 x 89 x 252 mm 16.7" x 3.5" x 9.9" in 1657: 340 x 140 x 336 mm 13.4" x 5.5" x 13.2" in |

| WEIGHT | Net: 6.8 Kg/15 Lbs. Ship: 9 Kg/20Lbs. |

| ENVIRONMENTAL | |

| TEMP. OPERATING | 0 to +40° C / +32 to +104° F |

| HUMIDITY | RH 5 to 95%, Non-Condensing |

Designed for Quick and Accurate Fault Detection on High Volume Production Lines.

Detects Fault Prior to Costly Reclamation.

Produces Rapid Go/No-Go Results for Faster Throughput.

Safe, Efficient, Easy-to-Use Safety Probes for Applying High Voltage.

Lockout Feature Shuts Off High Voltage if Product Fails.

Large Color LCD Display for High Voltage Output and Test Results.

Easy Menu Driven Operation.

Solid State Design for Durability in High Volume Product Testing.

Audible and Visual Failure Indicators.

Available Auto-Line Option for automated in-line production test.

Available Models

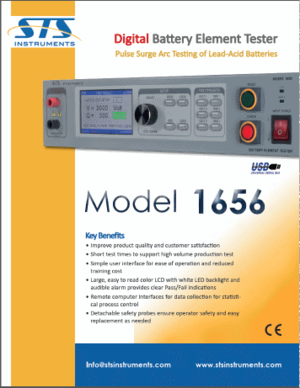

Model 1656 - Digital Battery Element Tester - Rack Mountable (NEW) (CE Compliant)

Model 1657 - Digital Battery Element Tester - Bench Model (NEW) (CE Compliant)

FEATURE COMPARISON TABLE:

(Discontinued Model 1652 verses Model 1656/1657)| FEATURE | 1652 | 1656/1657 |

| Test for SHORTS | YES | YES |

| Test for OPENS | NO | YES |

| Front Panel Setups | NO | YES |

| Large LCD Color Display | NO | YES |

| Remote Control Interface(s) | NO |

USB, RS232, RS485 |

| Programmable Test Time | NO | YES |

| Calibration Reminder | NO | YES |

| PLC Interface | NO | YES |

| Multi Language Menus (English, Asian) | NO | YES |

| Form Factor | Bench |

1657:Bench 1656: Rack or Bench |